Basisgegevens

Basis type:

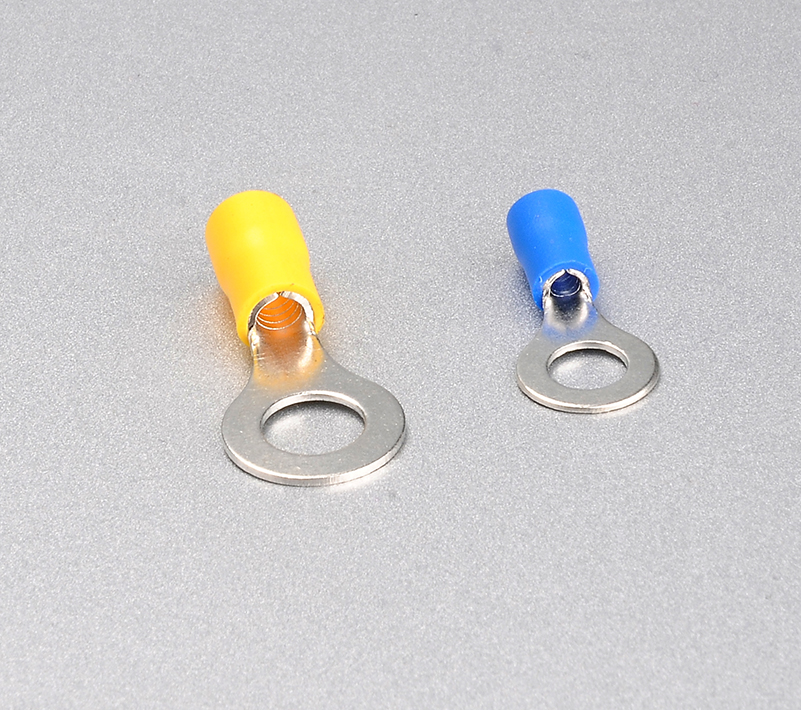

1.Isolearre single dirigint styl

2.Twin dirigint styl

3.Un-isolearre cord ein mouwen

Skaaimerken

Totale trochsneed: 0.25~150mm²

Kleurkodearring en buisdimensje neffens DIN 46228, diel 4 (0.5~50mm²)

Halide frij, Flame retardant kin akseptearje

Hittebestindich oant 105 ℃ (PP) 120 ℃ (PA)

Materiaal:

99% suver koper

Syntetyske: polypropylene (PP), polyamide (PA)

Oerflak

Tin-plated te beskermjen tsjin corrosie

Bestel ynformaasje

No ek beskikber yn handige plestik doazen foar lytsere easken.Under normale omstannichheden hawwe wy gjin MOQ-eask foar tasferpakking.

Technyske data

Geleidend materiaal (útsein Quick Connect Range)

| Koper | 99,9% suver |

| Treksterkte | 200 MPa |

| Duktile wurdearring | 35% |

| Finale Metal State | In part fan it produkt annealed |

| Oxygen ynhâld | 50 ppm max |

|

|

|

| Koper | 30% Sink 70% Koper |

| Treksterkte | 580 Mpa |

| Duktile wurdearring | 6% min |

| Finale Metal State | In part fan it produkt annealed |

|

|

|

| Materiaal | Tin |

| Tin Ynhâld | 99.90% |

| Oare metalen | Lead + Antimoanje |

| Plating dikte | 1,5 mikron |

|

|

|

| Algemiene konduktiviteit | 98,5% IACS |

| Totale resistiviteit | 1.738 mikro-ohm sm |

|

|

|

| Materiaal | PVC foar alle útsein nylon 6 of nylon 66 - foar IQC |

| Breakdown spanning | 1,5 k V(min) |

| Isolaasje ferset | Boppe 100 meg ohms |

| Working voltage | Oant 300V AC/DC |

|

|

|

| Pre-isolearje | -40 ℃ oant +150 ℃ |

| Koper | 145 ℃ |

| Tin plated | 160 ℃ |

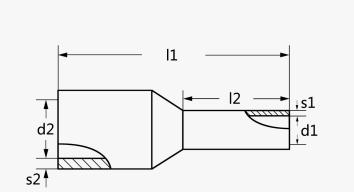

SPESIFIKASJE

| Dwerstrochsneed (mm²) | Artikelnr. | Ofmjittings (mm) | ||||||

| I1 | I2 | s1 | s2 | d1 | d2 | AWG | ||

| 0.34 | E0306 | 11 | 6 | 0.15 | 0.3 | 0.8 | 1.9 | #24 |

| E0308 | 13 | 8 | ||||||

| 0.5 | E0506 | 12 | 6 | 0.15 | 0.3 | 1.0 | 2.6 | #22 |

| E0508 | 14 | 8 | ||||||

| E0510 | 16 | 10 | ||||||

| E0512 | 18 | 12 | ||||||

| 0,75 | E7506 | 12 | 6 | 0.15 | 0.3 | 1.2 | 2.8 | #20 |

| E7508 | 14 | 8 | ||||||

| E7510 | 16 | 10 | ||||||

| E7512 | 18 | 12 | ||||||

| 1.0 | E1006 | 12 | 6 | 0.15 | 0.3 | 1.4 | 3.0 | #18 |

| E1008 | 14 | 8 | ||||||

| E1010 | 16 | 10 | ||||||

| E1012 | 18 | 12 | ||||||

| 1.5 | E1508 | 14.5 | 8 | 0.15 | 0.3 | 2.3 | 4.0 | #14 |

| E1510 | 16.5 | 10 | ||||||

| E1512 | 19.5 | 12 | ||||||

| E1518 | 25.5 | 18 | ||||||

| 2.5 | E2508 | 15.5 | 8 | 0.15 | 0.3 | 2.3 | 4.0 | #14 |

| E2510 | 17.5 | 10 | ||||||

| E2512 | 19.5 | 12 | ||||||

| E2518 | 25.5 | 18 | ||||||

| 4.0 | E4009 | 16.5 | 9 | 0.2 | 0.4 | 2.8 | 4.5 | #12 |

| E4010 | 17.5 | 10 | ||||||

| E4012 | 19.5 | 12 | ||||||

| E4018 | 25.5 | 18 | ||||||

| 6.0 | E6010 | 20 | 10 | 0.2 | 0.4 | 3.5 | 6.0 | #10 |

| E6012 | 22 | 12 | ||||||

| E6018 | 28 | 18 | ||||||

| 10.0 | E10-12 | 22 | 12 | 0.2 | 0.5 | 4.5 | 7.6 | #8 |

| E10-18 | 28 | 18 | ||||||

| 16.0 | E16-12 | 22 | 12 | 0.2 | 0.5 | 5.8 | 8.7 | #6 |

| E16-18 | 28 | 18 | ||||||

| 25.0 | E25-16 | 28 | 16 | 0.2 | 0.5 | 7.5 | 11.0 | #4 |

| E25-18 | 30 | 18 | ||||||

| E25-22 | 34 | 22 | ||||||

| 35,0 | E35-16 | 30 | 16 | 0.2 | 0.5 | 8.3 | 12.5 | #2 |

| E35-18 | 32 | 28 | ||||||

| E35-25 | 39 | 25 | ||||||

| 50,0 | E50-20 | 36 | 20 | 0.3 | 0.5 | 10.3 | 15.0 | #1 |

| E50-25 | 41 | 25 | ||||||

| 70,0 | E70-20 | 37 | 20 | 0.4 | 0.5 | 13.5 | 16.0 | 2/0 |

| E70-27 | 42 | 27 | ||||||

| 95,0 | E95-25 | 44 | 25 | 0.4 | 0.8 | 14.5 | 18.0 | 3/0 |

| 120 | E120-27 | 47,6 | 27 | 0,45 | 0.8 | 16.5 | 20.3 | 4/0 |

| 150 | E150-32 | 53 | 32 | 0.5 | 1.0 | 19.6 | 23.4 | 250/300 |

Us Service Guarantee